Products

The Tech-Roll hydraulic drum motors are simple: saving space and preventing damage by placing the hydraulic drum motor inside the drive roller. The end result is a motor that you can trust to deliver great durability and less downtime. The unlimited applications for the Tech-Roll™ drum motor include: food processing and equipment, agriculture equipment and processing, lumber mills, sawmills, mining, materials handling, and mobile operations. More information on Tech-Roll hydraulic products below!

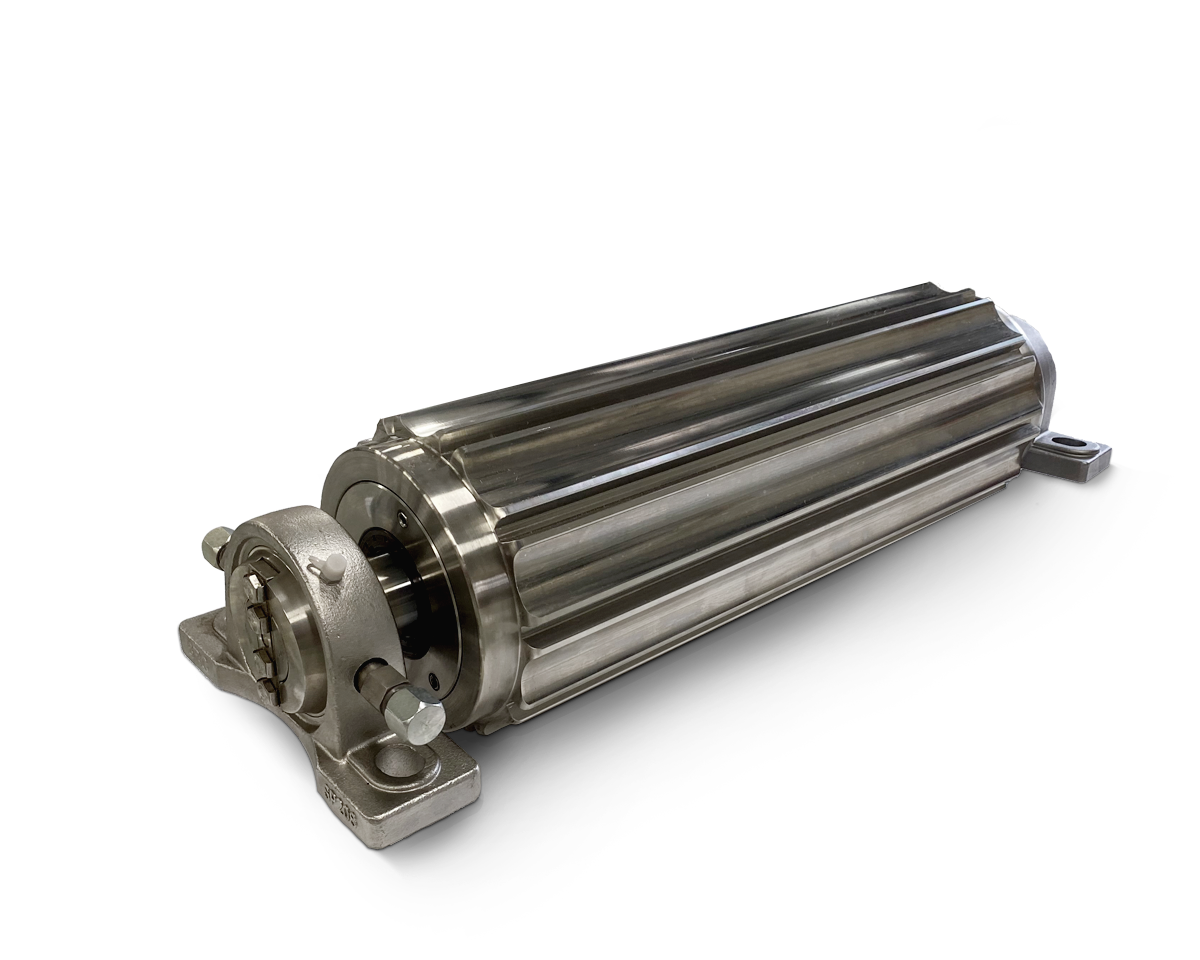

The New Tech-Roll Hydraulic Profiled Drum Motor

Tech-Roll has combined this new 316L stainless profiled shell design with the existing hydraulic all stainless steel Sanitary Drum Motor to provide the ultimate in sanitation, overall cleanliness, safety and return on investment.

Advantages of Tech-Roll

Except for the external bearings, Tech-Roll hydraulic drum motors or motorized pulleys, are maintenance free with no external moving parts — it is safe. The Tech-Roll motorized pulleys are also simple to install and can replace existing drives without conveyor modification. Therefore, the drive unit can be disassembled by removing only four screws and with no oil inside, it does not need to be sent out for servicing. Available in stainless or steel, Tech-Roll hydraulic products are ideal for HACCP inspected locations where they eliminate contamination from hard-to-clean external motors, couplers, chain drives, and oil leaks. And in wet areas where electric power is hazardous, including fishing vessels, this drum motor easily withstands high pressure saltwater wash downs.

Safe

No rotating parts outside a roller

Ideal for Wet Areas

No risk of electric shocks

Belting

Used with belting such as PVC, modular steel, plastic

Space Saving

Saves up to 20” of valuable space

Controllable

Easy speed control without electronics

Easy Retrofit

Uses standard bearing housings

Simple

10 minutes to disassemble and reassemble

Torque

Constant torque at all speeds and at start

Lagging

Lag with any materials, also can be knurled

Savings

Save by reduced maintenance & downtime

No Overheating

Cooled by return oil

Clean

Ideal for HACCP inspected areas

Explosion Proof

No electric sparks